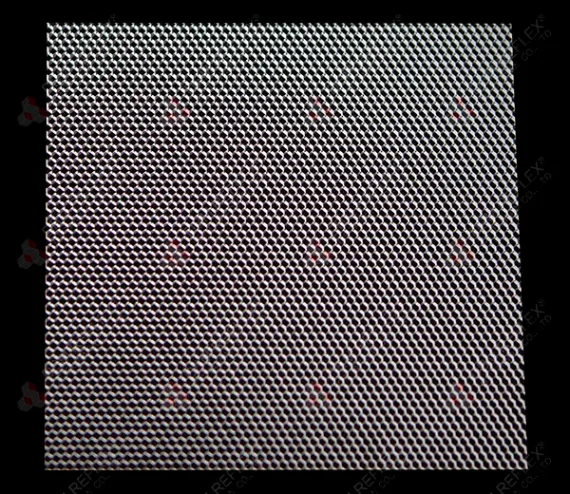

DBM Reflex manufactures all sizes, shapes and types of electroforms, employing the best materials, latest technologies and finest equipment.

DBM Reflex Patented Technologies (SUPERPIN™, Multiflex™) offer unique design solutions to automotive lamp makers.

PRODUCTION & QC EQUIPMENT

- 2 EDM & 3 Wire EDM

- 9 CNC Machines: 5-Aaxis (4); 3-Aaxis (5)

- 67 Plating Tanks

- Laser Welding Machine

- Microscopes

- Laser Pattern comparator

- Goniometer

- 2 Mitutoyo Coordinate Measuring Machine CMM

- 2 Molding Injection Machine

COMPUTER SOFTWARE

- E-form Design Dept.: CATIA-V5

- Optical Simulation: LucidShape

- Mold flow: Moldex 3D

Photometric Testing

Our Tainan factory is equipped with a goniometer lab with 30 meters tunnel for reflex reflector testing. Other automotive lamp functions can also be tested such as Head lamp, turn signal HMSL, ect.

After Sales

DBM專業的售服人員提供專業的知識與適當的模芯保養方式。 DBM也能協助試模調機讓客戶能得到最佳的配光數據,我司上海辦公室人員也一直與大陸一流的模具製造商保持交流合作。

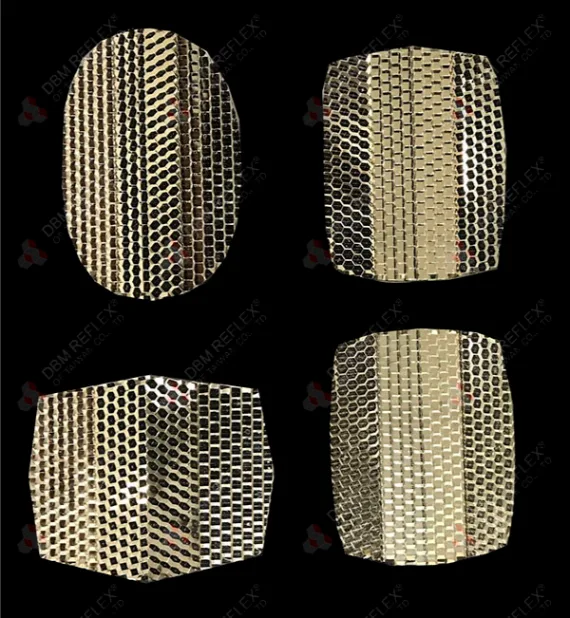

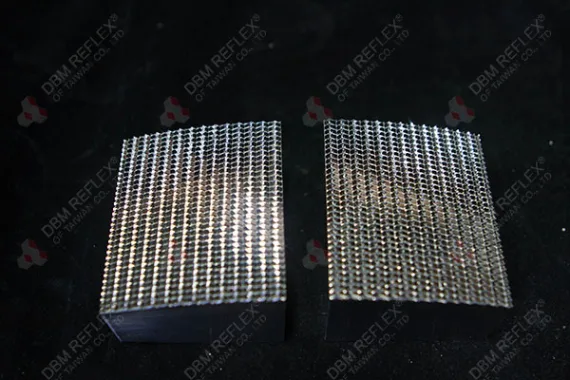

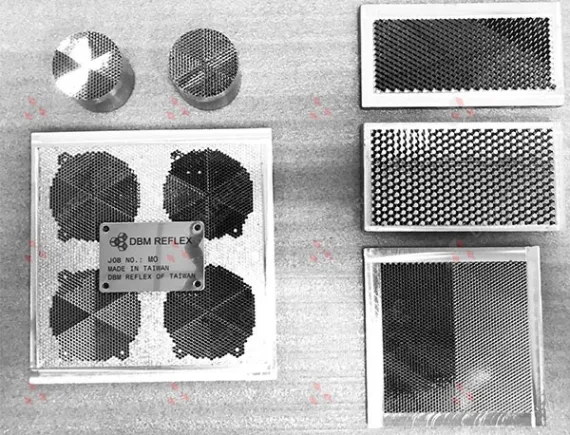

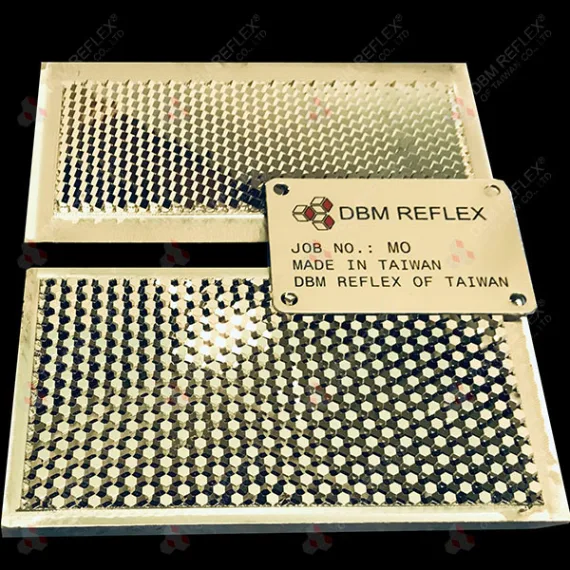

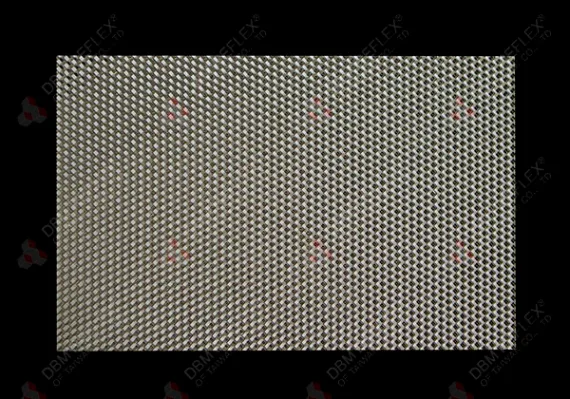

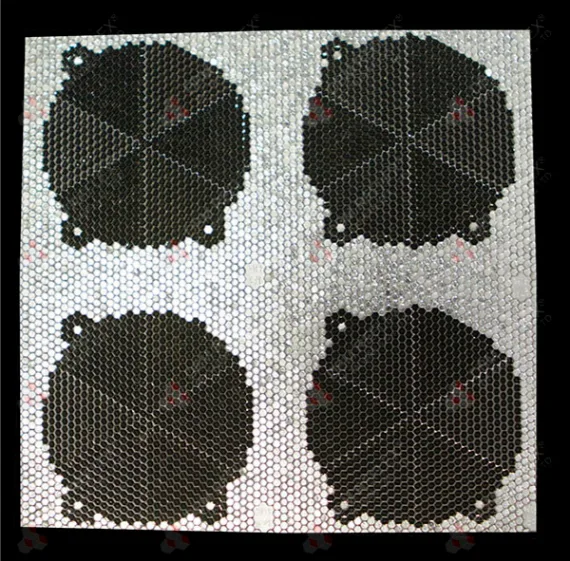

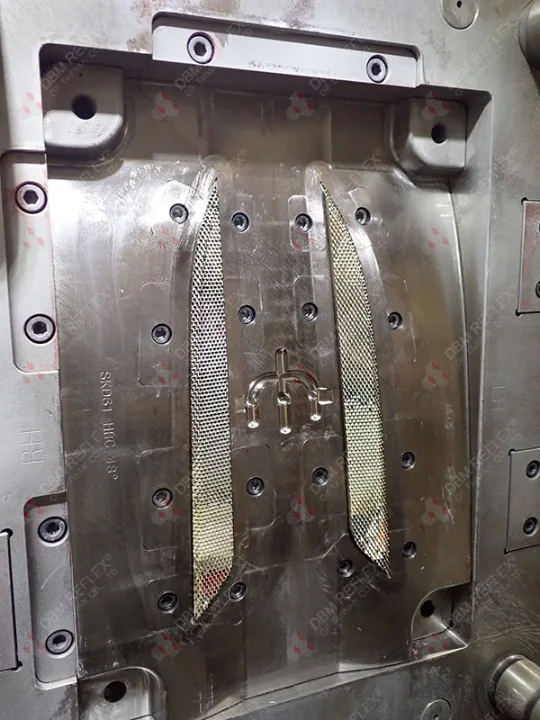

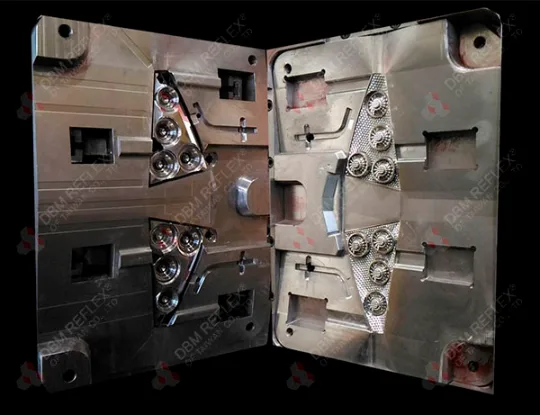

Warning Triangle Electroform Insert & Mold

DBM REFLEX supplies turn key solution for Advance Warning Triangle tooling compliant with ECE R27 or AIS 022. Nickel Electroform core insert and mold are built, tested and validated by DBM Reflex Taiwan. Samples complying with photometric requirement are supplied to customers for assembly. Warning triangle stripes with several pin layout arrangement are available.