DBM Reflex nickel Electroform inserts are used in plastic injection molds where they to provide

retro-reflection properties to optical polymer such as PMMA or PC.

retro-reflection properties to optical polymer such as PMMA or PC.

- Rear Combination Automotive Lamps

- Bumper Reflex Reflector

- Rear Fog Lamp RR

- Motorcycle Lamps

- Bicycle Reflectors

- Pavement Markers

- Warning Triangles

- Optical Sensors

- Our Expertise

Latest Technologies

DBM Reflex manufactures all sizes, shapes and types of electroforms, employing the best materials, latest technologies and finest equipment.

SUPERPIN™

DBM Reflex Patented Technologies (SUPERPIN™, Multiflex™) offer unique design solutions to automotive lamp makers.

Custom Made Electroform

Custom made curved electroform- free form surface- are commonly used in automotive lamps for their stylish design, while flat standard inserts are the economical choice for motorcycle RR, bicycle RR or road marker application.

Electroform Manufacturing

Creation of 3D Prisms models

Most car makers request realistic image of the lamp design, before tool are launched.

DBM have software tool that can easily install prisms to validate styling and identify possible appearance issue.

DBM have software tool that can easily install prisms to validate styling and identify possible appearance issue.

Design

With Solid 3D modeling using CATIA V5, the DBM design group creates all steps of the electroform manufacturing. Drawings are issued for all components and each department. 3D detail of prism geometry can be supplied to customers to validate aesthetic issues.

Pins

DBM Taiwan offer a wide variety of PIN shapes, sizes and grades to satisfy customers with advance design, innovative style of reflex and optimum performance. Various arrangements of prism or prism with optics to provide infinite design possibilities.

Plating Process

Nickel is electro-deposit on the master prism assembly reproduce the corner-cube accurate geometry. The electroplating process requires 3-4 weeks to obtain a 10 mm-12 mm thickness of Nickel.

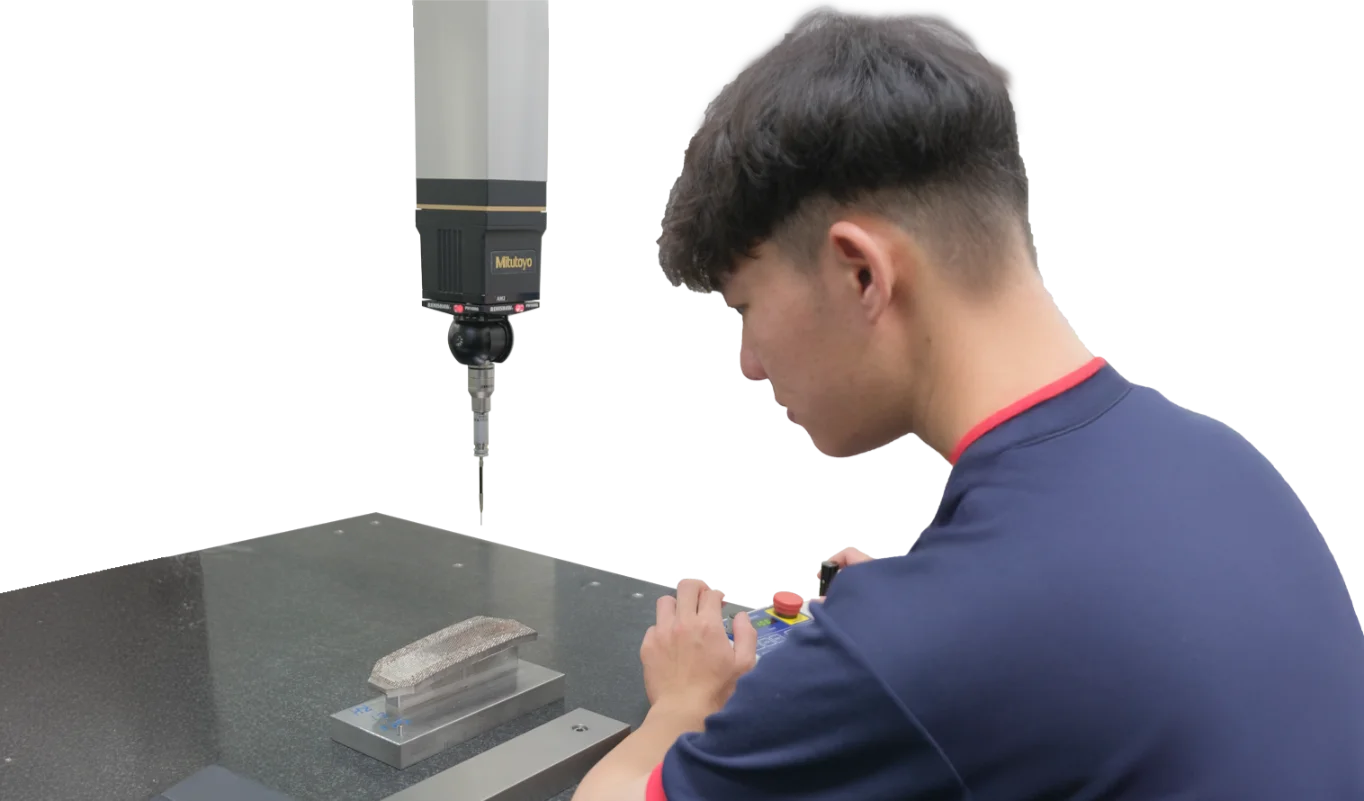

CNC Contour Cutting

Electroforms are well positioned and fastened on a steel back plate before final machining. DBM guarantees final machining with tolerances of +0.00 – +0.05 mm for easy fitting into mold pockets.

Deburing & Drafting

Under the view of microscopes, burrs and undercuts are manually removed using micro-air grinders and knifes.

Mold Reflex Reflector

Starting with extensive part design review / DFM / and Mold flow analysis, DBM team will design & manufacture injection mold especially for reflex reflector application.

DBM engineers have acquired experience of over thousands of RR projects and they can easily identify and avoid design flaw on RR lens design or mold structure that could affect reflex performance.

Mold trials are done in-house, with access to photometric lab for immediate performance validation.